What to do if the Asian machining parts are deformed

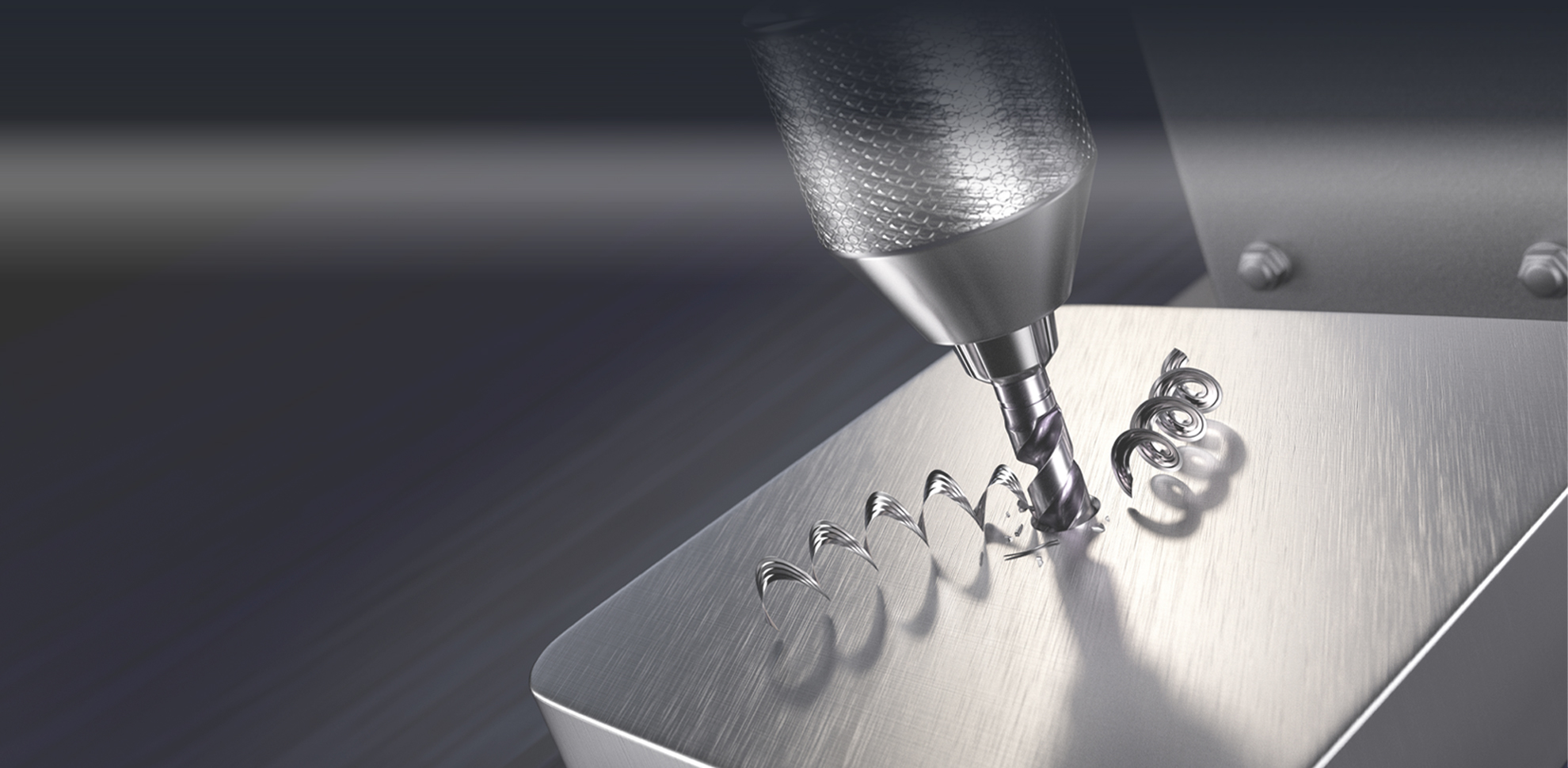

Hello, everyone, I’m the editor. The causes of deformation and cracking in parts processing in Asian machinery processing plants are various, such as material problems, heat treatment problems, structural design problems, process arrangements, and workpieces during wire cutting. The selection of clamping and cutting lines, etc. The main factors causing deformation and cracks are related to the structure of the parts.

1. The concave and convex molds with narrow and long shapes are prone to deformation, and the amount of deformation is related to the complexity of the shape, the aspect ratio, and the width ratio of the cavity to the frame. The more complex the shape, the greater the ratio of length to width and the ratio of cavity to frame width, the greater the deformation of the mold. The law of deformation is that the middle of the cavity is flattened, and the punch is usually warped.

2. Any quenching cavity with a complex shape and clear corners is prone to cracks or even bursts at sharp corners. The frequency of its appearance is related to the composition of the material and the heat treatment process.

3. Cylindrical parts with thinner wall thickness, if the inner wall is cut, it is easy to produce deformation, generally from round to oval. If it is cut into a gap, it is easy to burst when it is about to be cut through.

1. Deeper notches cut from the outside of the part are prone to deformation. The law of deformation is mouth adduction. The amount of deformation is related to the depth of the notch and the properties of the material.

The above is how to deal with the deformation of Asian machining parts? Do you understand it?

HTLCNC@163.COM

HTLCNC@163.COM

+086 18682444204

+086 18682444204